Floating Core (FC)

Insulated Duct

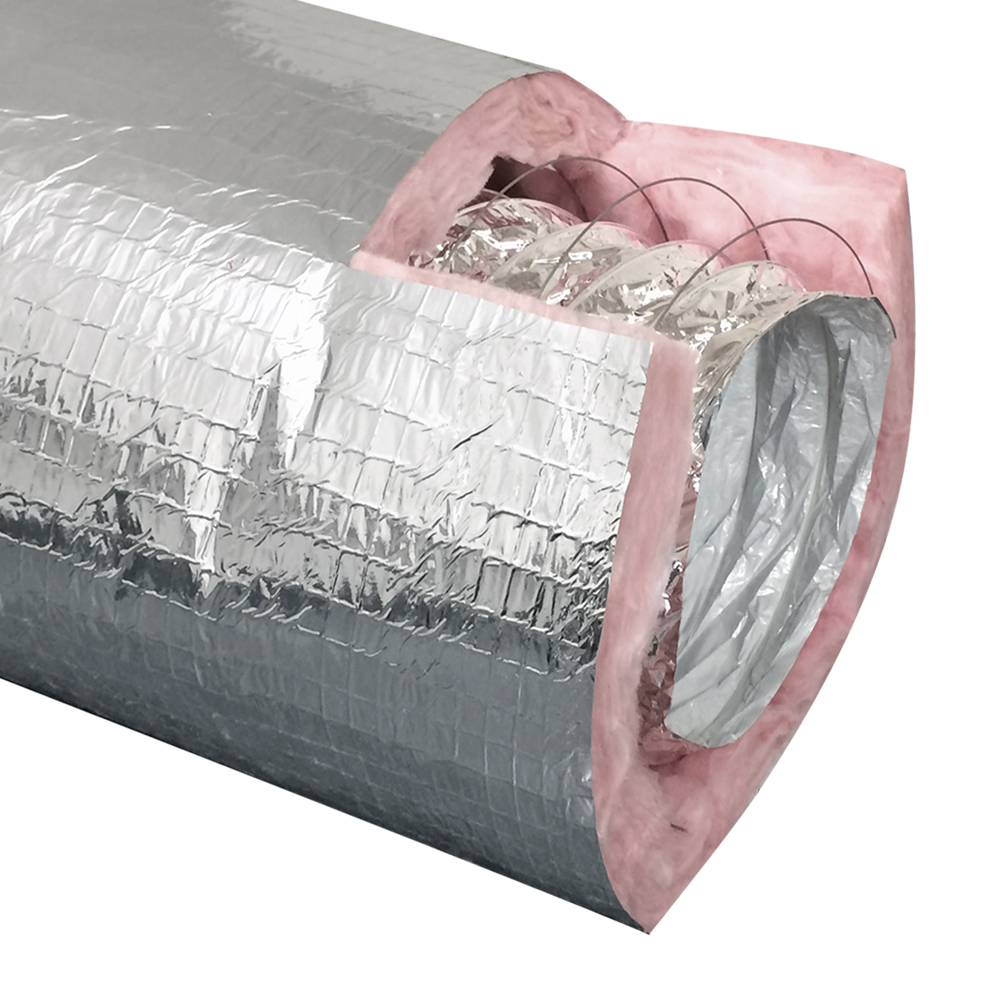

Thermaflex’s NEW patent-pending Floating Core (FC) Duct Construction adds a wire helix spacer between traditional bulk insulation and the reflective inner core creating a new and improved insulation system.

The addition of the wire helix spacer creates an air gap allowing the FC to be packaged up to 50% smaller than standard insulated flexible ducting. When unpacked, the Floating Core recovers 20% faster from the packaging allowing for quicker installation times.

The FC is a thermally insulated, fully lined, UL 181 Tested and Approved Class 1 Flexible Air Duct Construction that is also classified by Underwriters Laboratories using ASTM C-518 standard to determine thermal ratings. It’s designed for low to medium pressure cooling and heating HVAC systems.

Features & Benefits

- Underwriters Laboratories listed to UL 181.

- NEW additional steel wire helix spacer provides 3x greater crush resistance.

- Air gap and added wire helix spacer allows for smaller product packaging with no core damage (up to 50% smaller).

- Wire helix also assists in holding the fiberglass insulation away from inner liner during installation.

- Individual bag product will stand upright without any assistance (box-like characteristics).

- Once opened, packaged product can recover approximately 20% quicker.

- Available in both box and bag packaging.

- Complies with NFPA Standards 90A and 90B.

- Fully lined for efficient air delivery.

- The outer vapor barrier is a jacket of fiberglass scrim reinforced metallized film laminate.

- Made with Owens Corning™ EcoTouch® formaldehyde-free Insulation. Made with 99% natural materials and highest recycled content. Also, it is the only fiberglass insulation listed in the USDA BioPreferred Catalog.

- Available through broad national distribution.

- Patent Pending

Space Savings

The FC’s smaller packaging allows for more units to be combined on a single pallet. The pallet to the left shows 36 boxes of 6″ standard KM R8 Insulated Flexible Duct. The pallet to the right shows 60 boxes of the new 6″ KM-FC R8 Insulated Flexible Duct.

Construction & Materials

Strong polyester film laminated and encapsulating a heavy steel wire helix, forms the inner core. The outer silver film provides a reflective surface on the inner core. An oversized, loose, steel wire helix supports a thick blanket of fiberglass insulation creating an air gap between the reflective inner core and fiberglass insulation. The outer vapor barrier is a bi-directional reinforced metallized vapor barrier that will not unravel. The smooth airtight innercore of polyester is designed for low to medium pressure systems.

Warranty

The first five years of installation in the case of any warranty issue or product failure, Thermaflex® will cover all duct cost, material cost and any reasonable labor cost, provided the product was properly installed in accordance with our written installation. For the second five years of installation, for a maximum of ten and in the event of any product failure or warranty issue, Thermaflex® will make replacement of the defective duct only and no other cost will be reimbursed.